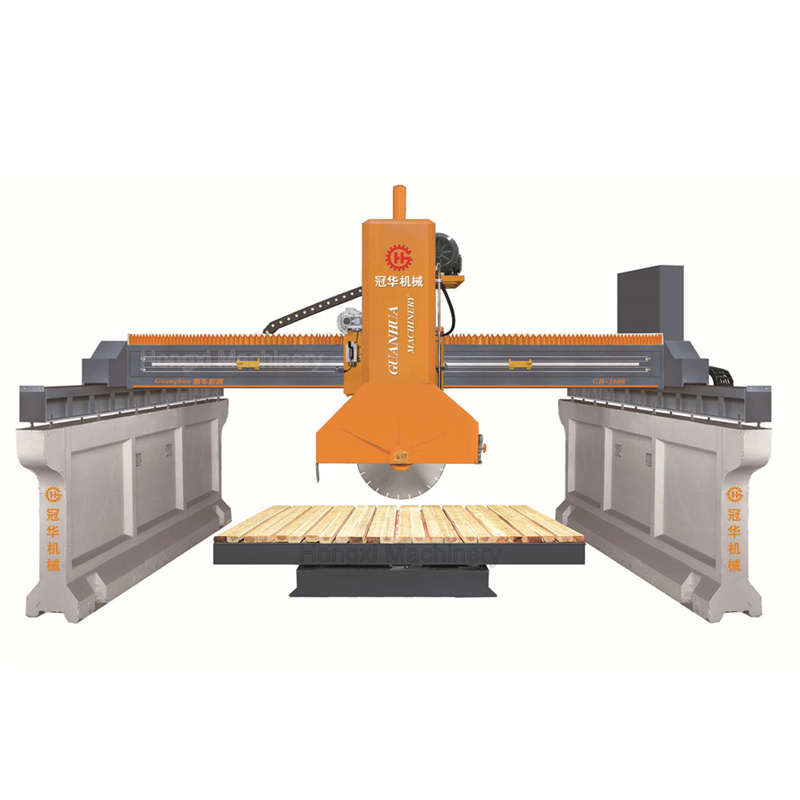

Infrared Slab Cutting Machine Bridge Saw Cutters for Stone Granite Marble Quartz

1) Controlled by PLC, operated expediently, accurately and stably.

2) Cutting head can tilt 45° for mitre cuts (Optional function).

3) Working table can tilt at 85 degrees for easy loading slabs

4) Worktable can rotates in 90degree or 360degreee.A full 360°rotating table enables precision cutting of material edges.

5) Laser device is adopted for slab positioning accurately.

1) Controlled by PLC, operated expediently, accurately and stably.

2) Cutting head can tilt 45° for mitre cuts (Optional function).

3) Working table can tilt at 85 degrees for easy loading slabs

4) Worktable can rotates in 90degree or 360degreee.A full 360°rotating table enables precision cutting of material edges.

5) Laser device is adopted for slab positioning accurately.

6) Touch screen control panel and all movement is controlled by PLC to realize operation available.

7) Crossbeam movement (Y-axis) along V-guide way with high precision.

8) Magnetic ruler is adopted for slicing measure.

9) V-guide rail system applies not only in left and right movement of the girder but also in lifting up and down section, thus reduces the error and improves cutting accuracy.

10) Good quality steel is used as the mechanical parts and reliable electric parts are used to guarantee high reliability & durability.

|

Voltage

|

380V or 220V

|

|

Main motor power

|

15KW

|

|

Maximum Processing Size

|

3200*2000*100mm

|

|

Cutting thickness (maximum)

|

80mm

|

|

Control method

|

PLC

|

|

Blade Diameter

|

Φ350-Φ450mm

|

|

Workbench tilting Degree

|

0-85degree

|

|

Workbench rotating degree

|

0-90degree or 0-360degree

|

|

Water consumption

|

4 m3/h

|

|

weight

|

5600kg

|

|

Dimensions (length × width × height)

|

5800×4800×2900mm

|

Reviews

There are no reviews yet.